|

C200 Air Operated Wire Crimp Tool

|

|

|

|

The CM

500W

is a table top low cost crimp tool which takes a variety of dies. Air

operated, using standard factory air (5 bar min), with a pressing

capacity of up to 1200kp, this portable device allows easy and

convenient change of tools and set up for different crimp contacts.

Compare this to equipment from national manufacturers at twice the

price. The C200 is built to crimp in a linear up and down fashion and

not like a standard scissors crimp which can wear tools out quickly.

Two crimp contact positioning and holding systems are available, a

simple crimp contact star for standard contacts, or a

positioning slide for holding both the crimp contact and the wire

|

|

|

|

|

|

|

|

Press

IDC onto Ribbon Cable

|

Crimp Large Gauge wire

|

Cut Pins

|

Split Ribbon Cable

|

C200 PDF Data Sheet

|

|

Wire

Crimping

|

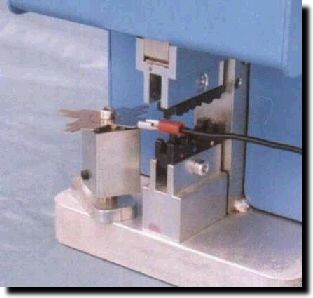

The positioning tool

depicted at the right is a flat star which allows the crimp contact to

be placed onto one of the blades and rotated into position between the

upper and lower die.The correct location for the leaf is set by a ball

detent. The operator places the wire into the crimp housing and steps

on the foot pedal for a quick and reliable crimp connection.

Tools for measuring the crimp height and the pull out force are also

available (see below.) For more precise locating of the crimp contact

and wire, a positioning slide is available which allows the loading of

the crimp contact and wire in front of the crimp tool. After

placing the crimp contact into the receptacle and inserting the wire

into the crimp barrel, the mechanism is moved forward to bring the

crimp barrel and wire between the upper and lower crimp die. Stepping

on the pneumatic foot pedal will actuate the crimping process. The

holding jig is on a spring loaded table which will move down slightly

as the upper crimp die brings the contact and wire into the lower crimp

die channel.

|

|

|

|

|

|

| |

|

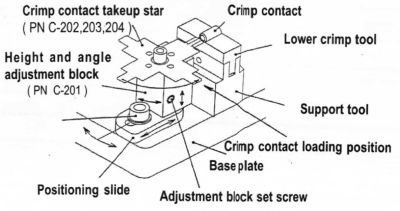

Position Blocks and Leafs

|

|

The C 200 is distinguished from

other economical

solutions for making wire crimp connections in medium volume, in that

it is provided with

a selection of tools to help the operator speed up the positioning and

increase the

accurracy of the crimping process. The positioning block with the

correct positioning leaf

aids in placing the crimp contact in position under the die set ,

leaving the operator

free from having to hold the contact near the die set.

|

| |

|

Crimp Dies

|

|

Crimp connections are available in

open or closed

barrel designs. The closed barrel can be insulated or

uninsulated. Tools for

crimping standard wire contacts to coaxial contacts and even fiber

optics are available

from different manufacturers. Depicted below are 3 standard crimp

tools available

off the shelf for crimping open barrels, closed barrels without

insulation, and insulated

closed barrel. The C200 is designed to take standard die sets from

Ideal and other

manufacturers. If you need dies for other types of crimp connections

such as Coaxial or

Fibre Optic contacts, please get in touch with our sales representative

and we can help

source those for you

|

| |

|

About

Crimping

|

|

A crimp

connection provides an electrical and a mechanical connection . The

measure of the quality for an electrical connection is the

conductivity. The measure of quality for the mechanical connection is

the pull out force. Both factors, the electrical conductivity and the

pull out force, depend directly on the crimp height of the conductor.

Using the crimp height caliper, this is measured from the bottom of the

claws to the highest point in the crimp.

|

|

|

Test measurements

have indicated that the optimum electrical conductivity (point E, Fig

II) and the optimum withdrawal force (point M, Fig. III) are not

related to the same crimp height. This means that a crimp with an

optimum electrical conductivity does not have the maximum achievable

withdrawal force - and vice versa.

|

|

It is necessary to

attempt to reach a compromise between the two ideal conditions (fig.

IV). This compromise point normally lies between the maximum values of

the two curves

|

|

|

| |

|

Wire size conversion tableAWG - mm2

|

|

AWG

|

mm2

|

AWG

|

mm2

|

AWG

|

mm2

|

|

1

|

42.400

|

11

|

4.170

|

22

|

0.330

|

|

2

|

33.600

|

12

|

3.310

|

24

|

0.200

|

|

3

|

26.400

|

13

|

2.620

|

26

|

0.130

|

|

4

|

21.200

|

14

|

2.080

|

28

|

0.080

|

|

5

|

16.800

|

15

|

1.650

|

30

|

0.051

|

|

6

|

13.300

|

16

|

1.310

|

32

|

0.032

|

|

7

|

10.600

|

17

|

1.040

|

34

|

0.020

|

|

8

|

8.370

|

18

|

0.820

|

36

|

0.013

|

|

9

|

6.630

|

19

|

0.650

|

|

|

|

10

|

5.260

|

20

|

0.560

|

|

|

|

| |

|

C1500 Digital Force Measurement Gauge and Stand.

|

|

|

The C1500 is a state-of-the art digital force measurement gauge capable of highly accurate measurements required in quality testing to determine the strength and functionality of all kinds of connectors and fitted components. This heavy duty benchtop device is designed to measure pull forces of wire crimp connections, crimp on solderless lugs, ring, funnel barrel, tongue and spade terminals terminated to wire. Please call 508 935 2282

for a PDF Data sheet.

|

|

| |

FKN SYSTEK,

INC. - 115 Pleasant St., Millis, MA. 02054 ,

|

TEL:

(508)

376-2500 FAX: (508) 376-2505 : E-MAIL:

fkn@fknsystek.com

|

|

Copyrightę 1997,

98 FKN Systek, Inc.08/17/03 Last

Update 05//25/11

|

|